We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!

CachedOur Form Fill Seal Machines not only automate the packaging process but also optimise it for maximum output. Benefit from faster cycle times and higher throughput. The reduced need for manual intervention translates into significant labour cost savings, enabling a quicker return on your investment.

CachedIntroducing our Twin Vertical Form Fill & Seal (VFFS) packaging system, engineered for high-speed packing of coal, wood pellets, and more. This innovative system represents the pinnacle of automated packaging technology, integrating two FFS machines to achieve exceptional output rates.

CachedROVEMA Form, Fill and Seal machines pack your product reliably and with highest output into flexible bags. Continuous or intermittent Forming, Filling and Sealing in one operation. The All-rounders for flexible changeover between packaged goods and bag shapes.

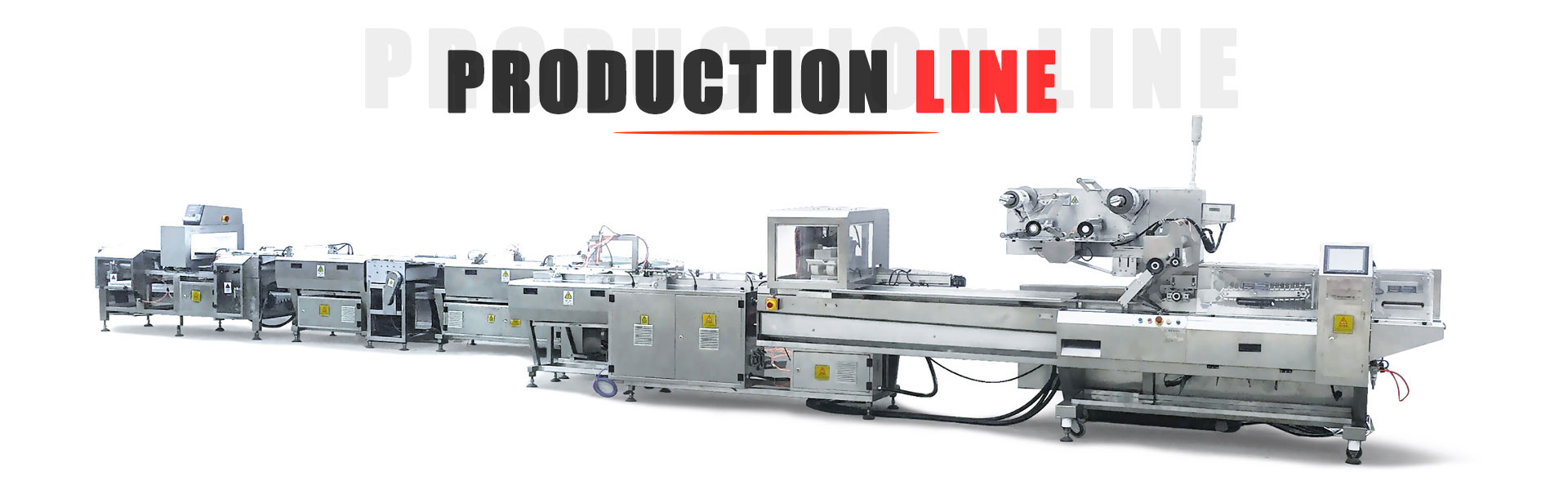

CachedForm Fill and Seal Machines at a glance. Our comprehensive machine portfolio, including continuous and intermittent Form Fill and Seal Machines for packing in film and paper, is designed to operate either as stand-alone systems or as a complete, highly automated in-line solution.

CachedDiscover versatile vertical form fill seal (VFFS) machines for efficient packaging of granules, powders, and liquids. Built for durability and reliability, browse our range today.

CachedJun 26, 2023 · Often, manufacturers use vertical form fill seal machines, an assembly that forms, fills, and seals flexible packages vertically. It creates bag pouches in different styles, including pillow bags, Doy packs, quad seal bags, and many others.

/en/solutions-portfolio/packing/form-fill-and-seal-machines/continuous/servo-xSee all results for this question

CachedWhether chain infeed or infeed conveyor, servo X machines win over with their continuous packaging process and no stop-and-go, meaning dead time is not an issue when sealing. Besides high performance, this enables extremely tight-fitting and precise packaging with a saving in film of up to 15 %.