We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!

The 1600 Series is an ideal solution for a variety of food and conveying applications. Are you interest in a longer belt life and a belt that can handle more weight? Reduce Downtime · On-demand Support · Safer for Employees · Safe for Food Contact Contact Us-Request Information Today-Learn More-Plastic Belts for Food-Metal Belts for Food

CachedOutfitting a commercial kitchen with a suite of commercial food service equipment that has earned the ENERGY STAR could save operators about 360. Contact Us Send Inquiry; French Fry and potato processing and packaging equipment . French fry potato processing and packaging equipment systems from Heat and Energy Saving & Pollution Control CEIA ...

2 Commercial Baking and Energy Use This section briefly describes the basic processes and typical energy consumption in commercial bakery plants. Energy use and intensity may vary from plant to plant. In their simplest form, most bakery products (bread, rolls, cookies, crackers) have similar ingredients and stages of production.

CachedSaving energy, resources, labor, and time with efficient food processing equipment is the best way to ensure you’re keeping these costs as low as possible. As the global population continues to increase, the demand for food is also expected to increase by about 60% by 2050.

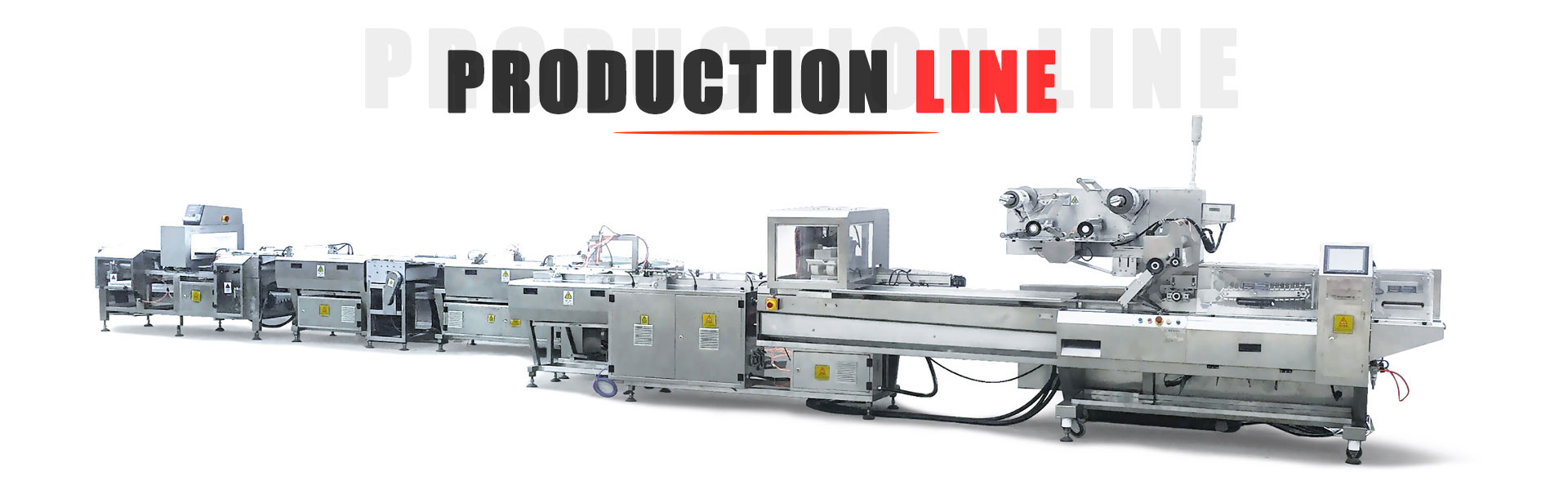

CachedBusch machinery offers most types of commercial food packaging equipment for bottling, canning, cartoning or other flexible types of packaging for bagging, including full line capabilities such as labeling, capping, cartoning, palletizing, blow molding and much more. Call for more information about our packing machines for food products.

Cached1 Introduction2 Materials and Methods3 Results4 ConclusionsFundingAcknowledgementsThe UK is committed to an 80% reduction in greenhouse gas emissions by 2050, compared with the levels in 1990 [1]. Catering businesses feature in virtually every town and city in the world and are vital buildings to be considered in any low-carbon plan. Commercial kitchens are some of the most profligate users of gas, water and electricity in the UK. As a result, they can leave a large carbon footprint, with relevant benchmarks (in kWh/m2) exceeding ten times the energy benchmarks of the majority of commercial premises (i.e. offices, retail premises, etc.) [2, 3]. The UK Carbon Trust and the Chartered Institute for Building Services (CIBSE) estimate that the total energy use of Britain's catering industry is in excess of 21 600 million kWh per year. CIBSE and the UK Carbon Trust estimate that 50% of this originates from non-commercial catering operations (hospitals, ministry of defence, schools, etc.), ∼20% is attributed to hotel and guest house kitchens and the remaining 30% origin... See full list on academic.oup.com 2.1 Description of the sample Fourteen sites in England were selected to take part in this study. The relatively small sample size reflects the practical and financial constraints of extensive monitoring of such appliances; the type of intensive analysis makes it difficult to target a large sample size [11], e.g. 400 individual appliances were monitored in this study. Each site belongs to a large chain of UK gastro-pubs, which comprises 191 premises, all offering the same food menu. The fourteen sites were selected owing... 2.2 Monitoring of electricity consumption Electricity supply was monitored using a system produced by a company—NoWatt Limited (Guildford, UK). The system consists of many purpose-built transformers that were fitted to breakers in the distribution boards of the incoming electricity supplies (Figure 1). Included in this were sensors. The sensors take sub-cycle readings at a rate of 12 800 times a second, enabling the differentiation of devices on a single circuit breaker by an advanced disaggregating software. The sensors are connecte... 2.3 Data analysis Whole building electricity and gas consumption was monitored for one year at one site to represent a case study of the gastro-pubs annual energy usage. This takes account of seasonal patterns of appliance use (such as heating and air conditioning) and consumer behaviour (such as increased ‘eating out’ in the holiday seasons). This information was analysed by business area and then by appliance end-use as described in Tables 1 and 2. Energy utilised in the boiler, providing gas central heating... See full list on academic.oup.com 3.1 Whole building energy use Figures 2 and 3 display the annual profile of energy use (% kWh) for the case study site (including gas). The results should be considered with caution owing to the singular sample case study and the different relative efficiencies between gas and electricity use. Considering the business areas, Figure 2 clearly demonstrates that the kitchen is by far the largest user of energy. In terms of end function, the cooking of food followed by the storage of food represents the largest energy-using a... 3.2 Total kitchen electricity consumption The average daily electricity consumption for the 14 kitchens is illustrated in Figure 4 together with the average number of meals served. This clearly demonstrates that consumption is only marginally affected by trade volume. As expected, there is increased consumption over the weekend. However, given a 152% reduction in meal output on a Monday compared with a Saturday (Figure 4), consumption only decreases by 20%. This is largely due to operator behaviour. Between the sites, there was signi... See full list on academic.oup.com Electricity use is vastly greater than literature estimates suggested with kitchen and food-related activities greatly outweighing other energy-using activities. Consumption is highly variable between kitchens and appliances due in part to the wide variety of makes and models of appliances implemented. The combined averaged consumption of refrigerated storage appliances in each kitchen equated to 41% of the average total electricity use within each kitchen, this represented the largest category of usage. The combined electricity use of hot-holding appliances (heat lamps and bain maries) represented 16%; the third largest electricity users were the grills. Poor levels of maintenance noticeably contribute to excessive energy use in refrigeration. Generally, correct sizing and consolidation of refrigerated storage will also see energy reduction benefits; this could include more frequent deliveries in an effort to minimise storage capacity. Current catering appliance design does not len... See full list on academic.oup.com This work has been supported and funded by the Technologies for Sustainable Built Environments (TSBE) centre, Reading University, in conjunction with the Engineering and Physical Sciences Research Council (EPSRC) and Mitchell's and Butler's plc. See full list on academic.oup.com In addition to the credited authors, special thanks must be made to NoWatt ltd, particularly for the assistance of Mr Allister Mannion, without which this study would not have been possible. See full list on academic.oup.com

CachedSo you're looking for Commercial Food Packaging Equipment and more. There are products and videos for you on the topic. See them below. Hopefully you'll find something in this category of "Industrial & Scientific Products - Food Preparation Equipment".

Looking for Cleaning & Food Packaging at Unbeatable Prices? Our Knowledgeable Staff Will Help You Find the best. Visit Us Today.

The 1600 Series is an ideal solution for a variety of food and conveying applications. Are you interest in a longer belt life and a belt that can handle more weight? Reduce Downtime · On-demand Support · Safer for Employees · Safe for Food Contact Contact Us-Request Information Today-Learn More-Plastic Belts for Food-Metal Belts for Food