We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!

CachedThe tube filling machines work with mechanical jaw sealing systems for aluminium tubes and with hot jaw/hot air systems for laminated and plastic tubes. All machines allow rapid size changes and dosages from 3 to 450 ml. Options available include automatic tube loading from a magazine, and plus customizations depending on the container (mascara ...

CachedAll of our semi automatic tube filling and sealing machines include manual tube loading, automatic orientation, automatic filling, automatic sealing, and automatic coding for plastic or metal tubes with speed ranges from 10 to 40 tubes per minute and sizes up to 300 ml.

CachedVKPAK offers four types of fully automatic tube filling and sealing machines, three models with capacities of 30-60 tubes per minute, and a high-speed multi-head filling and sealing machine. ( Each type can be customized to meet the packer's specific needs.)

CachedThe universal tube filling machine is a fully automatic tube filling and sealing machine capable of running both plastic and aluminum tubes at speeds of 30 per minute. Universal Tube Filling machine (80 tubes/minute)

CachedNorden Machinery is offering tube filling, cartoning and box/tray packing machines, handling everything from low and medium- to super high speed tube packaging. Discover more. EXHIBITIONS AND NEWS. Optimize your tube pre-forming process with Norden’s lower pre-closing jaws kit. 04/07/2024.

CachedUnited Pharmatek's Automatic Tube Filling machines are designed and engineered to produce outstanding quality and precision tube filling and sealing of aluminum tubes or metal tubes with the output of up to 90 tubes per minute. It is widely used in cosmetics, pharmaceuticals, chemicals and foodstuffs industries.

/machinesSee all results for this question

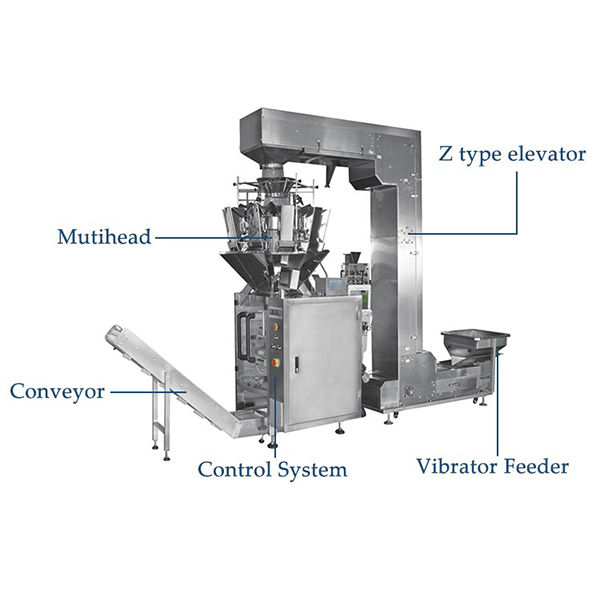

CachedCompact design and auto tube feed. Driving part fully-closed. Tube washing and feeding marking identification, filling, folding, sealing, code printing and finished product output all conducted by a fully auto control system.