We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!

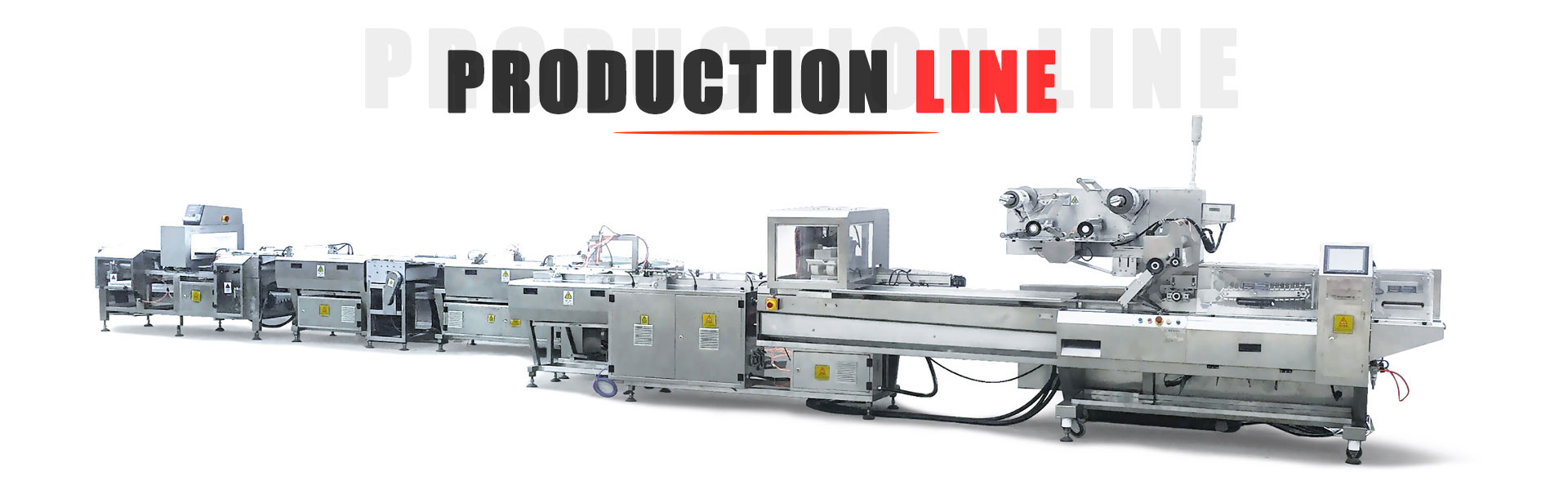

CachedIncrease Scale & Quality. Built with a patented flusher discharge conveyor for the smoothest loaf transfer, AMF’s bread packaging equipment helps you deliver higher quality baked goods at higher speeds. Automatic dual wicket exchange allows wicket change without stopping operation.

CachedAutomatic bread packaging machine. Fully automatic Countpack system is equipped with an elevator conveyor, multilane counting unit and bagging unit. Rolls or similar small bakery products can be imported into the counter directly from the production line, or through the elevator conveyor.

CachedPowerful automatic bagger with clipband closure capability suitable for sliced, whole or half loaf bagging, pita bread and various other bakery products. Loafmaster combines the latest, state-of-the-art advances in automation technology.

CachedPackaging machine for bread rolls, buns and similar bakery products. This bagging and clipband closure machine for bread packaging is a classic with which the Ipeka story began in the 70s. The CL-35 has remained popular for decades and the equipment has been delivered to over a thousand units.

CachedOptional automatic wicket changing mechanism; Machine is built from food graded stainless steel; Able to be fully synchronized with the operation of a bagging machine. Soft start, soft stop features reduce machine wear. Precision engineering design means reduced maintenance and less wear.

CachedPackaging machine for bread rolls, buns and similar bakery products. Fully automatic Countpack system is equipped with an elevator conveyor, multilane counting unit, and bagging unit. Rolls or similar small bakery products can be imported into the counter directly from the production line, or through the elevator conveyor.

amfbakery/equipment/packaging/bagging/See all results for this question

CachedFerguson Engineering design, manufacture, install and commission hot bread batching systems to suit almost any product and plant rate. Compatible with any depanning unit, hot bread conveyors are typically installed as a twin lane system for higher plant rates and a single lane system for standard plant rates.