We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!

Tmax Battery Equipments Limited. offers an extensive range of high quality Battery Packaging Machine and much more. Please visit: www.tmaxcn.com.

Obexion Max is simple, easy-to-use, and compliant — perfect for product recalls and customer returns of damaged batteries or devices. Damaged, defective, and recalled lithium-ion batteries (and devices that contain them) usually must be transported as fully regulated Class 9 shipments, requiring extensive labeling, documentation, function-specific training, and (depending on your carrier ...

In-house Battery Equipment Insights. The Targray Battery Division is focused on providing advanced materials and supply chain solutions for lithium-ion battery manufacturers worldwide. We also advise cell manufacturers on their R&D and pilot line equipment purchases, helping identify the best tools and production processes for our materials:. Single processing tools

Lithium Ion Battery Packaging. DOT Final Rule HM-224F incorporated a number of significant changes to the regulatory requirements for shipping lithium batteries and cells. Let HAZPlus help you comply with these new regulations. HAZPlus now offers compliant, easy to use packaging solutions for Lithium Batteries of all types.

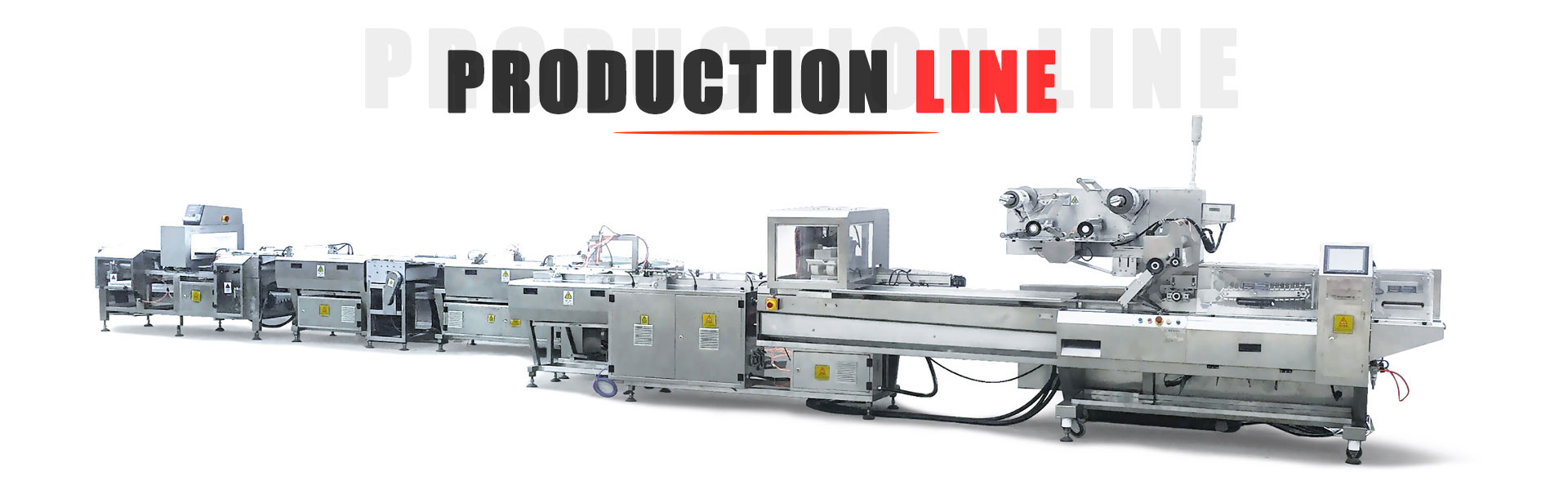

Xiamen Tmax Battery Equipments Limited was set up as a manufacturer in 1995, dealing with lithium battery equipments, technology, etc. We have total manufacturing facilities of around 2, 000 square meters and more than 100 staff.

Techland Manufacture Pouch Forming Machine, Electrolyte Filling Machine,Winding Machine, Tab Welding Machine, Ultrasonic Welding Machine, Mixing Machine, Slitting Machine, Sealing Machine, Stacking Machine Glove Box which are used for manufaturing battery's Techland has a strong experience in the field of battery manufacturing machines.

Cylindrical Battery Pack Sorting & Welding Equipment. www.mondragon-assembly.comMondragon Assembly is an international group specialising in the developmen...

Mill battery materials into smaller particles using milling machine. Use mixer to mix active, conductive and binder material into paste under vacuum. Using coater, coat paste onto current collector to make electrodes. Dry the newly-created electrodes using a heater. Use the rolling press (calendar) to roll the electrode to desired thickness.

The manufacturing of a lithium ion battery pack requires a series of manufacturing processes. Fig. 2 below shows the typical manufacturing processes used in current lithium ion battery manufacturing for EVs. For battery pouch cell manufacturing, first, the electrode materials (both LMO and graphite, separately) are uniformly mixed with carbon black additives and binders in NMP (N-methyl-2 ...

machine components, tools and services ... The packaging materials are generally to be ... Extensive literature is available for the properties of Li-Ion battery materials and their manufacturing ...