We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!

CachedRotary-system automatic pouch packaging machines. Our top-of-the-line series that performs forming, filling and sealing at an ultra-high speed of 200 to 1,000 pouches per minute. Three-side seal pouch. Four-side seal pouch.

CachedSED-FLB Series automatic pouch packing machine is specially designed for filling powders, such as pharmaceutical powders, milk powder, seasonings, milk tea powder, powdered detergent and so on.

CachedOur MH25 and MH250 pre-made pouch machines can handle different pouches and packs, with or without zips. They work with various bag sizes and can be used alongside automatic filling systems, multi-head weighers, powder fillers, depositors, and liquid fillers.

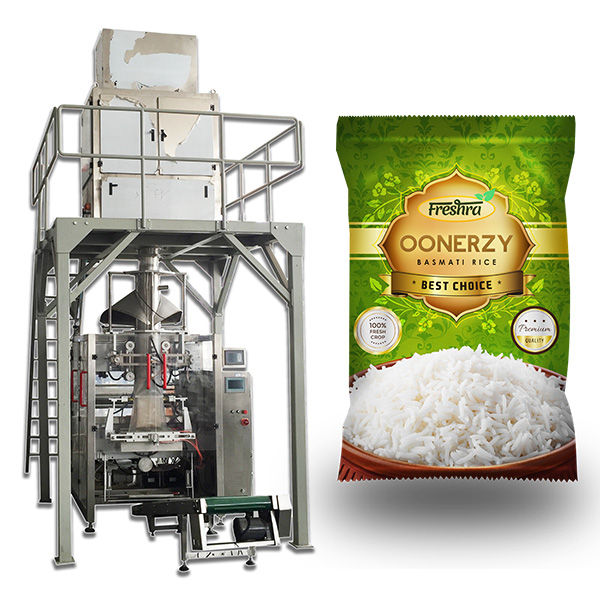

CachedPowder filling machines can be semi-automatic or fully automated and are able to be integrated with secondary machines that can heat seal flexible packages or cap and seal jars or pots, as well as in-line or rotary container handling systems for pots, jars and buckets.

CachedFor powder packaging applications, the servo driven Star Auger automatic filling machine offers precision, speed and versatility when handling powders and granules. Engineered to accurately dispense and fill a wide range of products, our automatic auger dispensing machine includes stainless-steel construction, easy-to-remove tooling and hopper ...

CachedPowder packaging equipment can automatically do the following task: weigh powders, divide products into proper serving sizes, fill bags and containers with powder products, seal the packaging and count the number of finished products.

topack.co.jp/english/about/automatic.phpSee all results for this question

CachedAutomatic Powder Packing Machine 1kg to 3kg for Sale. 1kg to 3kg automatic powder packing machine is extremely suitable for projects that have high production demand. It can automatically complete the process of feeding, weighing, filling, sealing, cutting, and coding.