We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!

CachedTo support our detergents we offer Auto-Dosing Systems and solutions to help you achieve maximum results with minimum waste. Auto-dosing gives you complete control of detergent usage in your laundry room and assists you in achieving the best possible cleaning results. Businesses We Supply We supply laundry detergents and auto-dosing kits to... Auto-Dosing Pumps For a competitive quote on automatic soap injection units,... Products AUTOMATIC SOAP INJECTION KITS Save Money With Soap Auto... FAQs We also ensure that our packaging is recyclable and... Testimonials Choosing MAG Laundry Detergents can bring many benefits to... Detergents Blog Commercial laundry detergents play a crucial role in... Contact Us Contact Us - MAG Laundry Detergents Stain Removers At MAG Laundry Detergents we prioritize the quality and...

CachedPowder Laundry DetergentLiquid Laundry DetergentDetergent Powder Filling Machine For CansDetergent Powder Filling Machine For PouchesLiquid Detergent Filling Machine For CansBenefits of Investing in Automated Packaging Machines For Detergent PlantsConsiderations When Customize Your Detergent Filling MachinesOther Packaging Machines to Add to Your Packaging LineConclusionPowder detergent is a more traditional washing solution that is both cost-effective and has considerable stain removal strength. The detergent powder has recently experienced a worldwide resurgence in popularity due to a number of factors, including its cost, which makes it a particularly practical market product for developing nations. Stains can ... See full list on levapack Liquid detergents have a greater capacity for releasing and dissolving fat, and the materials they include are resistant to the minerals usually present in hard water. Furthermore, since the liquid formulas keep the color better than powder detergents, liquid detergents are better suited for washing colorful clothes. The combined mass of dry materi... See full list on levapack Machine Function A can powder filling machine aids in the process of filling containers with substances that have been ground into powder form. A wide variety of freely flowing granulated and powdered goods are used in thepowder can packaging machine. It is crucial to guarantee that the can detergent powder filling machine performs its tasks accurately and has the ability to properly control the powder. Major Components Basic parts of the detergent powder filling machine can include: 1. Filling Motor: The volume of the packages is regulated by the filling motor, which manages the filling jar’s rate of revolution. 2. Mixing Motor: This motor controls how hard the blenders work to mix the powder. 3. Mainframe heads: Provides an outside barrier against potential mechanical harm. 4. Level Detector: The level of powder sprayed into the containers is determined by a level detector. Point level detectors and contin... Working Principle Two main motors, the filling motor, and the mixing motor drive the entire feeding process. These two drives cause the filling head’s agitation blades and blenders to rotate, homogenizing and deaerating the powder as a result. A combination of sensors and highly calibrated detectors control the flow and loading of the powder into the packages once it has passed through the funnel. One will be able to fill the cans more quickly using the double head filler because of its two heads. In compariso... See full list on levapack Machine Function Preformed pouches are empty bags made of paper or plastic. Only one opening remains to allow for the filling because the edges are sealed. A premade pouch packaging machine is made of components and devices that operate according to a predetermined order. The manufactured bag is picked up and passed forward in the process for filling and other operations. Major Components The basic components of the detergent powder filling machine for pouches are: 1. The code printer: Ensures the authenticity of your products. 2. PLC control systems: They are commercial computer systems used to manage various electro-mechanical operations in factories, plants, and other automated settings. 3. Bag opening device: This opens the premade pouches in order to fill them with the required powdered product. 4. Vibration device: In order to transport objects or bulk materials, vibrati... Working Principle A premade pouch packaging machine operates in a series of processes that are guided by its Programmable Logic Controller. The pouches are gathered by an automated robotic arm from a conveyor belt beneath it. Then the packaging machine system is loaded with the pouch. The bags are transported to the filling stage by the packaging machine’s revolving center. The premade pouches’ mouth is opened by a little lever. The open bag is moved and placed beneath the filling machine’s hopper. A weigher h... See full list on levapack Machine function A liquid filling machine is a device that is used in a variety of industries to package liquid finished products. Different sorts of packages are used for the packaging. These can be containers like buckets, tanks, bottles, tins, and cans. A liquid detergent filling machine provides flawless operation with remarkable precision. Major Components Some basic components of the machine include: 1. Collecting tray of the cork: This part is where the product that needs to be packaged is filled. 2. Panel with command buttons: It enables the operator to steer the device along the desired production cycle. 3. Can holder tray: It is the part that keeps bottles that need to be filled in the proper position. 4. Pivot wheels: It aids in relocating the equipment to the required locations. 5. A tank for collecting liquid: It usually has liquid that... Working Principle This liquid detergent filling machine runs smoothly and requires minimum human labor. They eliminate the necessity for human work. Both the arrangement and filling of the cans are performed mechanically. High precision and adaptability help to ensure that no leakages are noted. This is possible because the machine can fix the proper syringe sizes. Additionally, these devices include automatic speed variation adjustment. The conveyor can be adjusted to accept cans of different sizes. The devic... See full list on levapack Better quality checks are provided by this system. Minimum human interaction ensures fewer job errors which result in efficient production. Less and fewer items are found to be defective. Automated... See full list on levapack The Flow Characteristics of Your Detergent Products The viscosity of your product plays a major role in determining which detergent filling machine is ideal for it. A gravity or overflow filler is typically an excellent option for a free-flowing fluid but may not be the best option for a thick product. A pump filling machine or a piston filling machine will frequently work better for thicker goods. The Bulk Density of Your Detergent Products Bulk density is calculated by dividing the material’s mass by the total volume that it takes up. Particle volume, inter-particle void volume, and internal pore volume are all included in the total volume. High bulk density is preferred to cut back on detergent packaging and shipping expenses. On the other hand, agglomerated products’ low bulk density affects other powder attributes like flowability and instant characteristics. Variety of Shapes and Sizes of Detergent Containers There are countless sizes and varieties of containers available today, and the particular type you choose for your items can have a big impact on the kind of equipment that will fill it most effectively. Container positioning components are frequently seen in fully automated filling lines, and container shape has an impact on how the containers are positioned for filling, capping, or labeling. See full list on levapack Can Sealing Machines Needless to say, these are the most essential equipment for a better shelf-life of the products. It is used to seal the lid to the body of various containers, including pots, jars, PET cans, glass cans, plastic cans, aluminum cans, tin cans, paper cans, and others. The body of the can be composed of metal, paperboard, or plastic. The can lid is typically made of tin-plated steel. Advantages of this machine: 1. Error detection: When an error is found, it automatically stops, ensuring a secure... Can Capping Machines This is used for applying caps on packaging materials such as bottles, vials, etc. after the vessels are filled with the detergent. From opening resistance to simplicity and convenience of dispensing, various cap types serve different functions. The type of can cappingmachine that is most appropriate for a particular project will depend on the container or bottle, its purpose, and other elements. Benefits of Can capping machines: 1. Can be changed according to your needs. You can/tin capping... Can Labelling Machines These are basically the equipment that is used to apply the brand labels on the finished detergent packaging like, bottles, cans, etc. They can stick to a variety of surfaces, including glass, steel, aluminum, plastic, and fiber drums. Labeling and printing technology range from hand-held devices for straightforward label applicationto high-volume machines that enable fully automated printing and application procedures. Benefits of can labeling Machines 1. Works on uneven surfaces: Not all pa... See full list on levapack Various types of machinery are available for detergent packaging both powdered and liquid detergents and hence it is crucial to perform proper research before picking one for your company. Not all machines work for every type of product but incompetence in optimal utilization of existing multifunctional devices can cause a lot of unnecessary expend... See full list on levapack

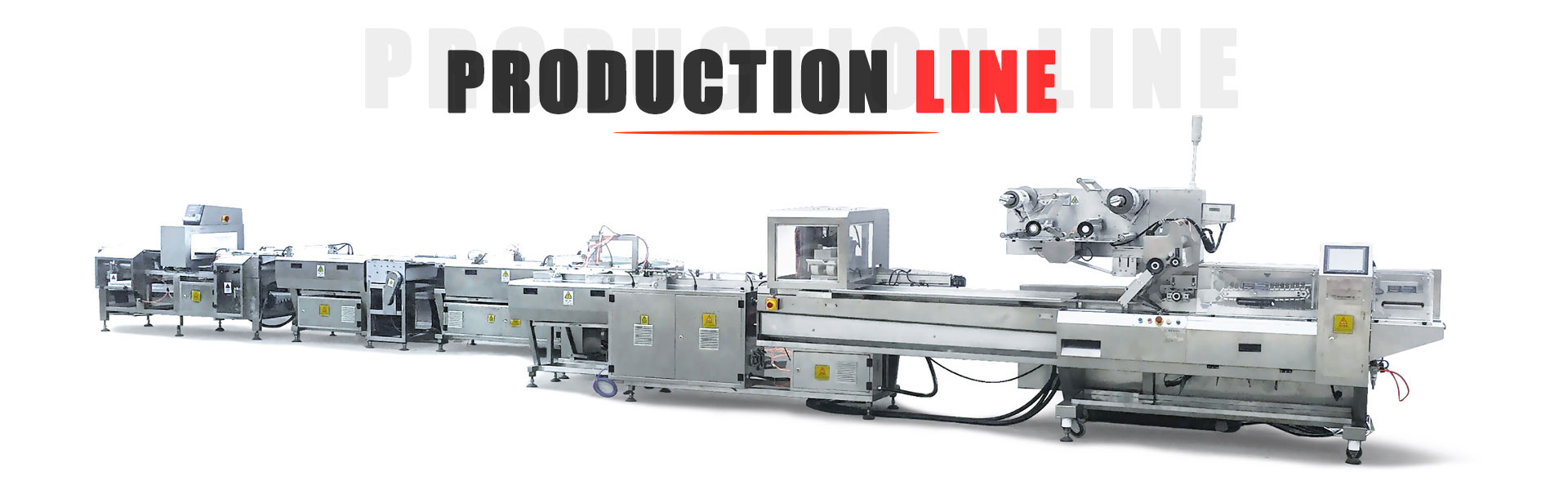

CachedAutomated solutions for packing laundry detergent, dishwasher powder, antibacterial powder and cleaning agents. Bagging, cartoning and hopper filling machines for powders built for efficiency, productivity and an optimized footprint. Volumetric and multihead weigher filling technologies available. Machines are used to automatically pack powdered detergent into bags or pouches. They can use plastic, paper, or woven bags.Features: adjustable we...The key components of an automatic detergent powder packaging machine include:Hopper - Stores bulk detergent powder and metered doses to the weighi...Lintyco focusing more on technical and Your business impacts:Automated filling solutions optimize detergent manufacturing workflows through high-ef...Packaging Speed and CapacityBefore you buy a food packaging machine, you need to have some idea of what your product is expected to achieve, for ex...Proper Handling and Storage of Detergent PowderStore in a cool, dry location away from direct sunlight and temperature extremes. Excess heat/moistu...Quality is maintained through features like weight controls, vision inspection systems, and reject mechanisms to ensure correct filling amount and...The machines mentioned can handle detergents with different fragrances and additives and offer various bag closure mechanisms. They can package bot...Integration with other equipment and remote monitoring capabilities are possible depending on the machine.Most machines can handle a wide range of bag sizes and materials like plastic, paper and woven pouches.The packaging speed is controlled through settings for the weight dosing, conveyors and filling systems.

CachedJan 27, 2023 · Discover the key factors to consider when choosing a detergent powder automatic packaging machine for your business. Make an informed decision and improve your packaging process with our expert guide.

CachedUnleash the Cleaning Power: Flow Commercial Laundry Detergents, in tandem with our state-of-the-art Automated Dosing Systems, are engineered to tackle the toughest stains, grime, and odours, leaving your linens, textiles, and garments looking and feeling as good as new.

CachedExplore & find the best laundry pods automatic packing machines for your factory . NPACK Automatic PVA film liquid detergent pods capsule packing machine is a rotary type single cavity small dose liquid dedicated filling & vacuum wrapping equipment.

/See all results for this question

CachedResults 1 - 25 of 106 A broad range of Detergents: Car Wash resources are compiled in this industrial construction and farming equipment, mining, machine shops, waste care products including car wash, dishwashing and laundry detergents.