We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!

CachedValve bag fillers rapidly and accurately package a wide range of granular and powdered materials. Machines like this typically bag cement, minerals, fertilizer, resins, chemicals, flour, sugar, starch, and wood. Valve baggers fill 20 to 110 lbs. of material per bag and are suited for manual, semi-automated, and fully automated manufacturing.

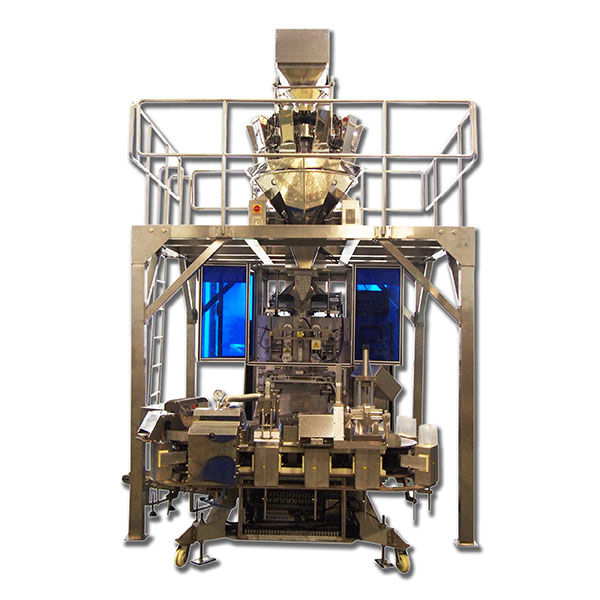

CachedThere are four main types of valve bag filling machines including auger fillers, impeller valve bag fillers, gravity-fed, and air packers. The filling process can be manual, where an operator places a bag on the spout, or it can be fully automated using a robotic valve bag placer.

CachedThe Industrial Auger Valve Bag Filler is designed to bag an extensive variety of abrasive powders which require a machine that is easy to use, dependable, and durable. To meet these demands, it is constructed with continuously welded thick wall box steel tubing for rugged and continual use.

CachedPlaces empty bags on the packer’s fill spout and stacks filled ones directly on a pallet on the floor. Compatible with air, auger, and impeller valve bag fillers. Up to 5 bags/minute (300/hour) Upgraded. VPV Series (former DB-700 Series)

CachedVersatile machines that pack powders into valve sack bags. Weights from 5kg - 25kg. Valve Sack Filling Machines are designed and constructed for heavy industrial environments.

CachedThroughput: 0 p/h - 180 p/h. Capacity: 10 kg - 50 kg. Valve bag auger filler with integrated gross weigher for powdery, floury up to small-granulated products such as flour, starch, coarse meal, iron oxide, dry mortar, plastic ...

/valve-bag-fillers/See all results for this question

CachedAuger packer: Uses a screw or auger to fill bags with product. Difficult to feed materials like starches and flours to granular material can be packaged with an auger packer. Impeller packer: Uses an impeller or slinger to “sling” the product through the fill spout to the bag.